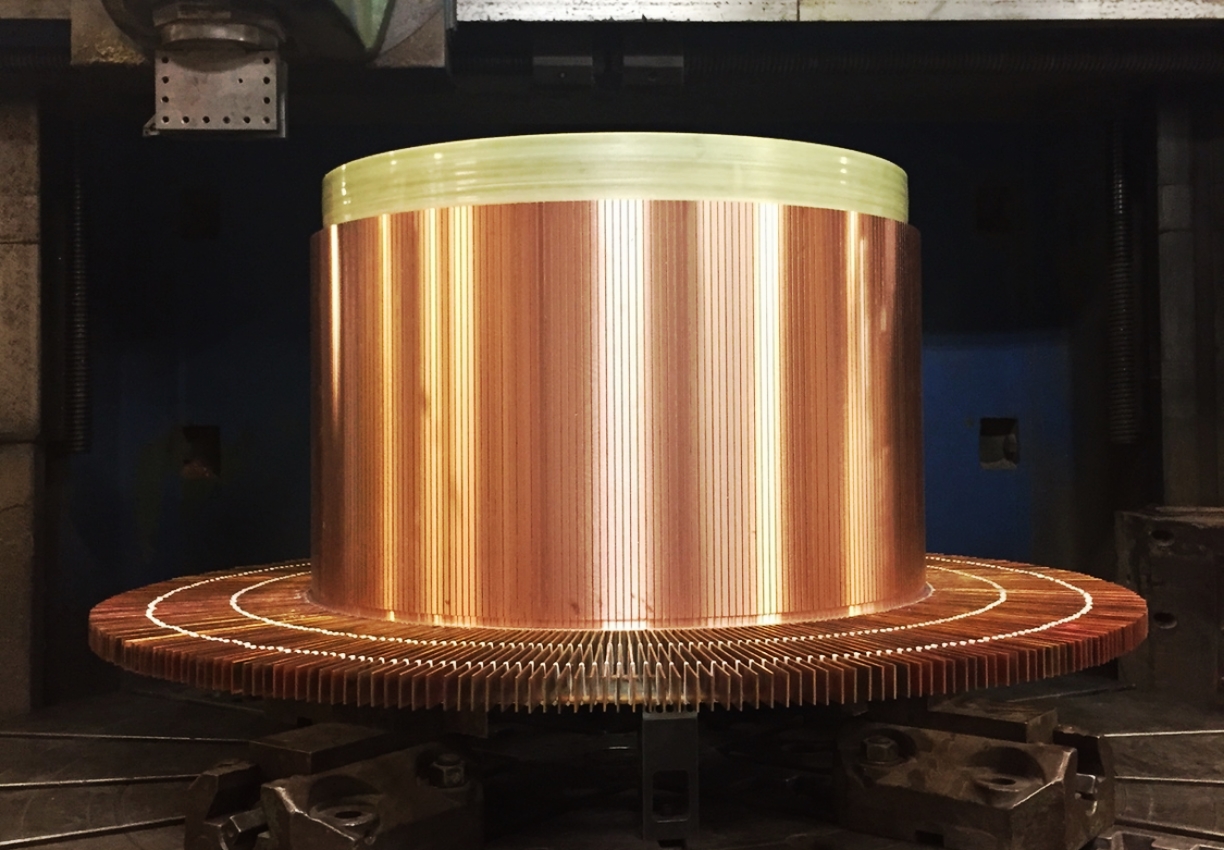

V-RING COMMUTATORS

V-ring commutators are the most common type of commutator. They are available in a wide range of sizes, from two inches to several feet in diameter. Appropriate to most applications, v-ring commutators can have different riser styles to accommodate different sizes and coil configurations. V-ring commutators are designed with the copper and mica segment pack retained on the inside. The interior of the segment pack assembly is cut in a dovetail, typically using 3° and 30° angles. A steel assembly including a spool for the center and two caps for either end, is then used to retain the segment pack. Matching angles on both caps fit into the cut dovetail angles on the segment pack, (insulated by mica v-rings) forming a clamp which retains the copper bars by exerting pressure on the 30° interior angle.

Dovetail pictured showing 3° and 30° angles.

The seating of the steel caps to this internal angle is critical to stable commutator operation, and sufficient curing is necessary to allow for the differential expansion of the steel to the copper. This curing helps insure that the segment pack does not loosen in operation. V-ring commutators closed with a nut at the outboard end are normally seen in a range of 2" to approximately 12". Larger units use bolts to secure the steel. Sample torque values for use in tightening these units during maintenance can be found in the Motor Fax section of this site.